The process of biological degradation of organic wastes is typically used as secondary treatment. Secondary treatment is designed to biodegrade substances such as human waste, food wastes and detergents. For this purpose microbes are used to consume biodegradable soluble organic contaminants and bind the less soluble fractions into floc which can later be removed.

Secondary treatment systems are categorised as either fixed film or suspended growth.

In fixed-film treatment, microorganisms are grown on media and the wastewater passes over the surface of the film. There are several processes in use. The most common fixed film configurations are trickling filters and rotating biological contactors. Other fixed film configurations include biological aerated filters, fluidized bed reactors and membrane bioreactors.

Trickling filters

Trickling filters may be configured as a shallow, naturally ventilated circular filter bed or as a packed tower with forced air circulation. Typically used media are activated carbon, limestone chips or specialised plastic media. Wastewater is distributed through perforated rotating arms radiating from a central pivot. This is an aerobic system where films of bacteria, protozoa and fungi reduce the organic component of the wastewater.

Rotating biological contactors

Rotating biological contactors (RBCs) incorporate an aerobic zone with rotating discs which are used to bring micro-organisms into contact with wastewater. Coagulants for the removal of Total Phosphorus may also be used in rotating biological contactors.

Biological aerated filters

Biological aerated (or anoxic) filters (BAF) usually consist of a reactor filled with filter media which supports micro-organisms. Wastewater is passed through this filter which can be operated in either an up flow or down flow configurations. Biological carbon reduction, nitrification or de-nitrification (anoxic) is combined with filtration in this unit to remove organics from wastewater.

Membrane bioreactors

Membrane bioreactors (MBR) combine a membrane liquid-solid separation process with activated sludge treatment. In this unit, low pressure microfiltration or ultra filtration membranes are typically immersed in an aeration tank. MBR eliminate the need for clarification and tertiary filtration.

Fluidized bed reactors

In a fluidised bed reactor, wastewater flows upward through an immobilized enzyme bed filled with suspended filter particles.

In suspended growth treatment, biota intermixes with the wastewater. Suspended growth treatment takes place in aerated vessels where primary treated sewage is combined with a biological floc to consume the organic component of wastewater in a process known as the activated sludge process (as shown in Figure 3). Activated sludge processes may also include a stage where the mixed liquor is treated under anoxic conditions (meaning that there is no residual dissolved oxygen) to remove nitrogenous matter or phosphate.

There are a number of unit configurations for suspended growth treatment however, all utilise dissolved oxygen to promote the growth of micro-organisms. This commonly occurs using either diffused or surface aeration.

Diffused aeration

Wastewater is run into deep tanks with diffuser blocks attached to the floor. Air is pumped through the blocks and a curtain of bubbles is formed which both oxygenates and mixes the wastewater.

Surface aeration

The general arrangement for surface aeration involves vertically mounted tubes which extend from just above the base of a deep concrete tank to just below the surface of the wastewater. When the tube is rotated, the vanes spin wastewater up and out of the cones drawing new wastewater from the base of the tank.

The two most common unit configurations for the activated sludge process are oxidation ditches and deep shafts.

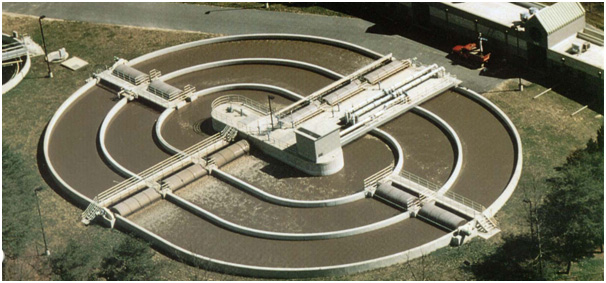

Oxidation ditch

In an oxidation ditch wastewater is treated in large ditches where flow is driven around the ditch by horizontal aerators. Oxidation ditches have a larger footprint than deep shaft configurations.